What is Luxury Vinyl Tile?

For the past few decades, sheet vinyl was the most popular choice right behind tile for locations where moisture- and stain-resistance was an issue, such as kitchens, bathrooms, laundry rooms, and basements. This type of vinyl flooring is made from a very thin layer of vinyl that has a printed design layer that is covered with some type of protective coating; it is prone to scratching and tearing, and it can feel quite hard underfoot, especially if it is installed over concrete substrate. Sheet vinyl must be installed over a perfectly smooth subfloor, otherwise the smallest imperfections will transfer through in the form of humps and dips.

In response, to improve some of the downfalls of sheet vinyl, manufacturers developed a new type of vinyl flooring, known as Luxury Vinyl Flooring, or LVF. Luxury vinyl flooring is sold in rigid planks called Luxury Vinyl Plank (LVP) or rigid tiles called Luxury Vinyl Tile (LVT). These types of flooring are installed using the similar interlocking edges that are found in laminate flooring.

Luxury Vinyl Planks (LVP) are mostly designed to simulate the look of wood, as is most laminate flooring, while Luxury Vinyl Tiles (LVT) are usually designed to simulate stone or ceramic tiles. The newest forms of luxury vinyl are so good at mimicking the look of wood, that more and more customers are choosing Luxury Vinyl Planks (LVP) over laminate flooring.

What is Luxury Vinyl made of?

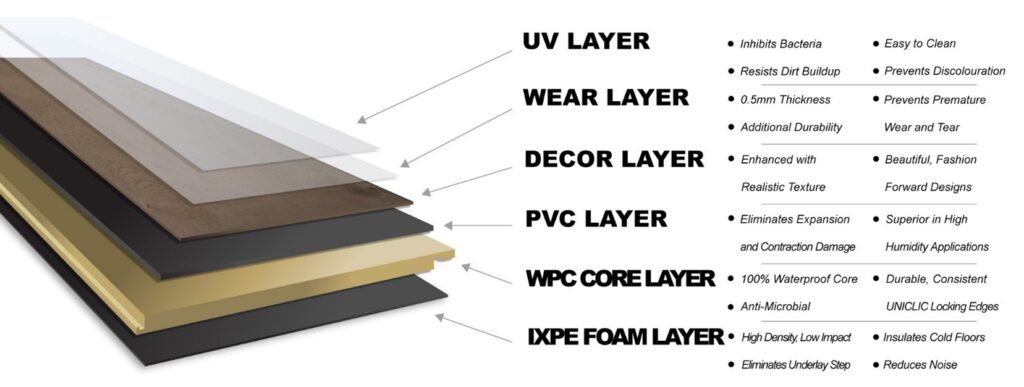

Luxury Vinyl Plank (LVP) flooring is made up of 6-8 structural layers such as a foam, cork or PVC backing, WPC or SPC core, PVC layer, a layer of glass fiber, print layer, design layer, wear layer and UV protective and in some cases, an added antimicrobial layer. The superiority of these layers and their excellence of engineering will determine the quality of the luxury vinyl plank flooring, therefore not all Luxury Vinyl Planks (LVP) are created equal.

Vinyl Composite Tile or Luxury Vinyl Flooring?

Vinyl Composite Tile (VCT) as it is often referred to is a very low cost, good wear option. Often used in healthcare or education environments due to its high traffic resistance. Color and design options are limited, maintenance is much higher requiring initial wax coating for protection and routine strip and re-wax applications.

Luxury Vinyl Tile/Luxury Vinyl Plank (LVT, LVP) are great low-cost alternatives with a low material and installation cost, lots of design options, and very easy to install and maintain. This makes this a great flooring alternative for modern day residential and even light commercial use.

WPC vs SPC

One of the most debated differences is the rigid core material that enables the floating installation of Luxury Vinyl Plank (LVP) floors without the need of glue. Planks with a rigid center allow for increased durability and better stability. Solid cores are water resistant and mask minor imperfections in the subflooring, making them a better choice when installing over an existing floor. Some Luxury Vinyl Planks have a solid Wood Plastic (or Polymer) Composite core or WPC. WPC does not contain actual wood. Instead, it is made up of wood flour fused with thermoplastic and calcium carbonates. The other type of core used in Luxury Vinyl Planks (LVP) is Stone Plastic (or Polymer) Composite or SPC core, that is typically comprised of around 60% calcium carbonate (limestone), polyvinyl chloride and plasticizers.

Both options are known for being 100% waterproof. SPC is a newer product with a signature rigid core that is virtually indestructible. WPC has been the gold standard for vinyl flooring and features a waterproof core that is comfortable, as well as functional.

Wood Plastic Composite (WPC) Characteristics:

- Retains more warmth than SPC vinyl

- Less dense underfoot

- 100% waterproof

- Easy to install, interlocking tongue & groove

- More affordable than real wood

- Slightly more expensive than SPC vinyl

- DIY friendly

Stone Plastic Composite (SPC) Characteristics:

- Gets cold easier than WPC vinyl

- Dense and rigid underfoot

- 100% Waterproof

- Easy to install, interlocking tongue & groove

- Superior density

- Slightly more affordable than WPC vinyl

- DIY friendly

Does Luxury Vinyl plank thickness matter?

You might think that Luxury Vinyl Planks (LVP) are better if the actual planks are thicker. This is simply a misconception that stems from the known fact that the old sheet vinyl floors where better quality if they were thicker. With rigid core Luxury Vinyl Plank (LVP), the overall thickness of the vinyl planks really does not matter, now that flooring manufacturers have created an ultra-thin, super-durable option. Rigid core Luxury Vinyl Planks (LVP) and Luxury Vinyl Tiles (LVT) are specially manufactured to be ultra-thin, usually measuring no thicker than 6-8mm.

On the other hand, when it comes to the thickness of the actual wear layer on the top of the plank, a thicker layer is more resistant to scratching and denting. Better quality flooring tends to have the highest wear layers but is more expensive. Building professionals often choose Luxury Vinyl Plank (LVP) flooring with a minimum of 12 mil for residential, and up to 28 mil for commercial projects.

The level of wear on a vinyl plank is measured in “mil” (one thousandth of an inch). A “mil” is not the same as a millimeter, as roughly 40 mil equals 1.0 mm (39.4 mil to 1 mm, to be exact).

Depending on your San Diego lifestyle, you should look for luxury vinyl flooring with a wear layer of at least 12 mil. If you have an active family or an assemblage of pets, consider buying 20 mil or higher.

Luxury Vinyl Flooring PROS and CONS

PROS:

- Durable. Vinyl flooring is designed to withstand the wear and tear of today’s active families, homes with pets, commercial use, and high traffic applications.

- Affordable. Luxury vinyl plank is both a cost-effective option as a floor-covering and the installation costs are also lower when compared to hardwood or tile installation.

- Ease of care. Vinyl is very easy to clean, won’t scratch easily, and can handle humid environments. It is generally dust free and can be maintained commercially by buffers making it a very functional floor covering.

- Availability and Designs. Luxury vinyl is widely popular and highly available, currently taking the majority of the floor covering sales in the USA. Luxury vinyl planks and tiles range in designs from stone looks, wood looks, concrete looking tiles, solid colors – there is a wide range of styles to choose from.

- Faster installation. As we mentioned, installation for your luxury vinyl planks should cost you less and your project should also be completed much sooner when compared to hardwood or tile flooring. Instead of demolition of your existing floors, vinyl flooring is often laid right over the existing hardwood or tile flooring saving both time and money in your remodel project.

CONS:

- Substrate preparation. Due to the thickness of vinyl flooring along with its flexibility, luxury vinyl flooring can transfer and really show imperfections in your subfloor. Extra care must be taken when preparing your plywood or concrete slab for installation, often extra self-leveling needs to be done prior to installing your new vinyl sheet goods, planks or vinyl tiles.

- VOC/Emissions: In glue-down installations, there are times where the adhesives used during installation cannot guarantee a VOC (Volatile Organic Compounds) free installation.

- Can’t be used outside or in a shower. Luxury vinyl cannot be used in wet environments. Though the planks are often labeled waterproof and are very moisture resistant, they cannot be installed in fully submerged applications, showers or outside where it is subjected to extreme weather changes and direct sunlight.

Is Luxury Vinyl Flooring any good?

While that answer varies for some of our customers, if you have an active family looking for a low cost, beautiful floor option that can be installed quickly and efficiently, well this is a great fit.

The pros outweigh the cons for many projects.